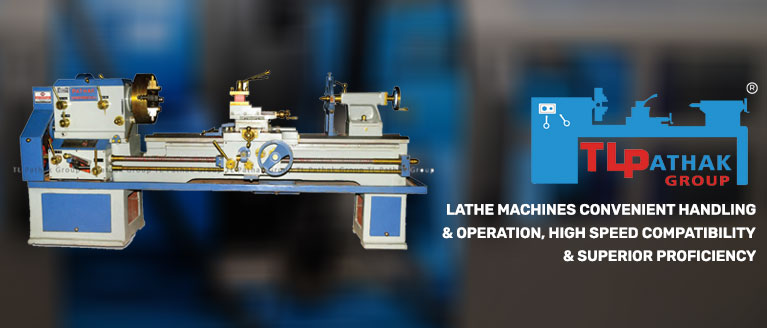

Lathe Machines Convenient Handling and Operation, High Speed Compatibility And Superior Proficiency

Published On: Oct 10, 2022 by Pathak

A lathe machine is a woodworking or metalworking tool that rotates an object on its axis in order to shape it. The object being worked on is held in place by a chuck, while the cutting tool is moved across the object's surface. Lathes can be used to create a variety of objects, including bowls, spindles, and other decorative items.

Parts of a Lathe Machine

A lathe machine is a tool that helps shape and form metal, wood, or other materials. The parts of a lathe machine include the headstock, tailstock, carriage, bed, spindle, and tool rest. The headstock is the part of the lathe machine that holds the workpiece in place. The tailstock is used to support the other end of the workpiece. The carriage is used to move the cutting tool across the workpiece. The bed is used to support the workpiece during operation. The spindle is used to rotate the workpiece during operation. The tool rest is used to support the cutting tool during operation.

Types of Lathe Machines

There are three main types of lathe machines: engine lathes, turret lathes, and chuckers. Engine Lathes: Engine lathes are the most common type of lathe. They are used to create cylindrical parts with smooth finishes. The cutting tool is mounted on a movable carriage that travels along the length of the workpiece. The cutting tool can be moved in and out, as well as side to side, to create different shapes. Turret Lathes: Turret lathes are similar to engine lathes but have a turret instead of a carriage. The turret holds multiple cutting tools that can be quickly changed out as needed. This allows for faster production times since the operator does not need to stop and change tools manually. Chuckers: Chuckers are another type of engine lathe but with one major difference – they have a chuck instead of a carriage. Chucks hold the workpiece in place while it is being cut. This makes them ideal for making small, precise cuts on delicate parts.

How to Operate a Lathe Machine ?

Assuming you have some prior experience with machinery, operating a lathe machine is relatively simple. The following guide will show you how to operate a lathe machine in just a few easy steps.

- Before beginning any work, it is essential that you read the manual for your specific model of lathe machine. This will ensure that you are familiar with all of the safety features and functions of the machine.

- Once you have read the manual, set up your work area. This includes positioning the machine in a well-lit and ventilated space, as well as ensuring that there is ample room around the machine for you to move freely.

- The next step is to select the correct tooling for the job at hand. Depending on the material you will be working with and the desired finish, different tooling may be required. Consult your manual or an expert if you are unsure which tools to use.

- With the machine and work area set up and the correct tools selected, you are now ready to begin operation. Start by feeding the material into the chuck slowly and carefully, making sure that it is straight and free of any defects.

- Once the material is secured in the chuck, use the controls to adjust the speed and depth of cut as needed. Always start with a shallow cut and increase depth gradually as needed.

- As you become more comfortable with operating the lathe machine, you can experiment with

Advantages of Using a Lathe Machine

There are many advantages of using a lathe machine. One advantage is that it is convenient to handle and operate. Another advantage is that it is compatible with high speed settings, which makes it ideal for advanced machining projects. Finally, lathe machines offer superior proficiency, meaning that they can produce precise and accurate results.

Disadvantages of Using a Lathe Machine

Like any other machine, lathes also have their own set of disadvantages. Some of the common disadvantages of using a lathe machine are listed below:

- Limited to cylindrical shapes: The biggest disadvantage of using a lathe machine is that it is limited to creating cylindrical shapes. If you want to create anything else, you will need to use a different type of machine.

- Requires skilled operator: Another downside of lathe machines is that they require a skilled operator. If you don't know how to operate one, then you won't be able to get the most out of it.

- Can be dangerous: If not used properly, lathes can be dangerous. There have been cases where people have been injured while using them. So, it is important to be careful while operating a lathe machine.

Conclusion

From the lathe machines we reviewed, it is evident that there are many benefits to using them. They offer convenience in handling and operation, high speed compatibility and superior proficiency. With so many advantages, it's no wonder that lathe machines have become so popular in recent years. If you're looking for a machine that can help you complete projects quickly and efficiently, a lathe machine is definitely worth considering.

Lastest Articles

-

Embracing NC Hydraulic Press Brake Technology in Middle East Factories

Being a prominent center for indust... -

What machines are used to set up an Electrical Modular Box Plant

Attention all aspiring entrepreneur... -

Manual Process For Making Steel Almirah

Steel almirah are not only durable ... -

Semi Automatic Almirah Making Machines

Streamlining Production Processes w... -

Steel Almirah Manufacturing With Fully Automatic High Precision Machines

Welcome to the world of precision a... -

Unlocking the Power of Precision Understanding the Purpose and Functionality of Drilling Machines

A drilling machine is a tool used f... -

A Beginners Guide to C-Frame Presses for Industrial Applications

Welcome to the world of C-frame pre... -

Busbar Machine Applications in Automotive Manufacturing

Busbar Machine Applications i... -

How Busbar Machines Contribute to Electrical Safety and Reliability

How Busbar Machines Contribute to E... -

A Beginner's Guide to Busbar Fabrication and Assembly

A Beginner's Guide to Busbar Fabric...