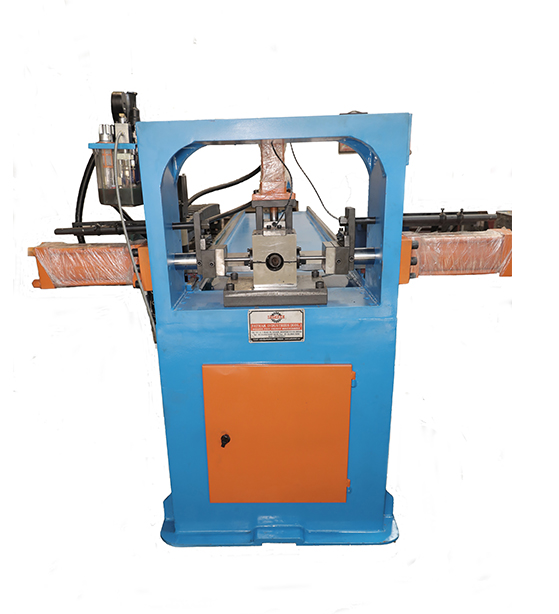

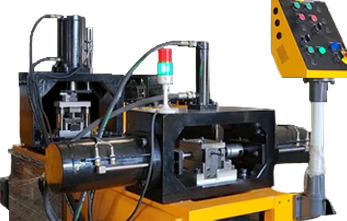

Special Purpose Machines Manufacturer in India

Description of Special Purpose Machines :

A special purpose machine (SPM) is a highly customized and automated device designed to perform specific tasks or processes with exceptional precision and efficiency. It is built to meet the unique requirements of a particular manufacturing or production process, eliminating the need for manual labor and reducing human error. SPMs are widely used in industries such as automotive, electronics, pharmaceuticals, and aerospace, where repetitive and complex operations are involved.The design and construction of an SPM are tailored to the specific application it serves. The machine incorporates advanced technologies, such as robotics, computer control systems, sensors, and actuators, to perform its specialized functions. It may consist of multiple interconnected components, including mechanical structures, tooling systems, conveyor belts, and inspection mechanisms, all working seamlessly together to achieve the desired outcome.

The primary goal of an SPM is to enhance productivity, accuracy, and speed while ensuring consistency and repeatability of the manufacturing process. These machines can handle intricate tasks like precision machining, assembly, testing, quality control, and packaging. By eliminating manual intervention, SPMs reduce the chances of errors, increase production rates, and improve overall product quality.One of the key advantages of an SPM is its versatility. It can be programmed and reconfigured to accommodate different products or variations within a product line. This flexibility allows manufacturers to adapt quickly to changing market demands, making SPMs a cost-effective solution for high-volume production.

Use of Special Purpose Machines :

Special purpose machines (SPMs) find extensive application across industries due to their ability to perform specialized tasks with precision and efficiency. Here are some key areas where SPMs are commonly used:

1.Automotive Industry: SPMs are employed for tasks such as engine assembly, welding, painting, and quality control. They ensure standardized production processes, reduce cycle times, and improve overall efficiency.

2.Electronics Manufacturing: SPMs are crucial for tasks like PCB assembly, component placement, soldering, and testing. They enable high-speed and accurate assembly of electronic devices, ensuring quality and reliability.

Overall, the use of SPMs in various industries leads to increased productivity, improved product quality, cost savings, and enhanced worker safety. These machines have revolutionized manufacturing processes by automating specialized tasks and ensuring consistency, accuracy, and efficiency in production operations.

Why We Called This Machines Special Purpose Machine ?

Special purpose machines are a category of machines designed for specific tasks or functions, contrasting with general purpose machines that can perform a wide range of tasks. The term "special purpose" emphasizes their limited scope of functionality and their tailored nature.These machines are built with a clear focus on accomplishing a particular task efficiently and effectively. They are often designed to optimize specific processes, increase productivity, or solve unique challenges. By narrowing their purpose, special purpose machines can excel in specific domains, such as manufacturing, scientific research, or data analysis.

The designation of a machine as "special purpose" acknowledges the targeted approach taken during its development. These machines are typically engineered with specialized components, software, or configurations to enhance their performance in the designated task. They may also exhibit increased reliability, precision, or speed compared to general purpose alternatives.