Category Lathe Machines - List of All Types of Lathe Machine

A lathe machine is a tool that helps remove material from the surface of the workpiece. Lathe machines perform various operations such as cutting, knurling, drilling, deformation, facing, and turning. The lathe machine is a necessary machine tool used in the metalworking industry. Numerous types of metal cutting machines, such as lathes and shaping machines, use single-point metal cutting tools. The value of the angles depends on the metal being cut.

Good Tool Room Lathe

A device room lathe must be as particular as viable. This may now not usually be feasible. Metal cutting paintings are done at very low speeds every so often. To get excessive-velocity consequences, it's miles obligatory to use splendid remarkable machines. There are four types of gear used in any woodworking store. A lathe has an extensive base that has numerous spindles and cones on top of it. Those spindles and cones, when assembled, shape a cone or many cones that make the first cut. The activity of the first lathe was to cut out substances and then push the material into the second lathe. The significant parts of a lathe machine are the bed, tailstock, top slide, apron, saddle ross slide, lead screw, headstock, chuck, gears, and tool rest; The bed is the base of a lathe; the chuck holds and spins the workpiece.

Accessories of Lathe Machine

Steady Rest : A lathe or grinding device wherein long spherical portions of labor might also rotate; however, without eccentric motion, Steady rests are wanted when the duration and stiffness of a work piece make it hard to devise without distorting or deflecting the component.

Follower Rest : The follower relaxation is to hold long or small diameter paintings from deflecting while a slicing tool is carried out. Long narrow shafts that tend to whip and spring while they may be machined require the use of a follower relaxation.

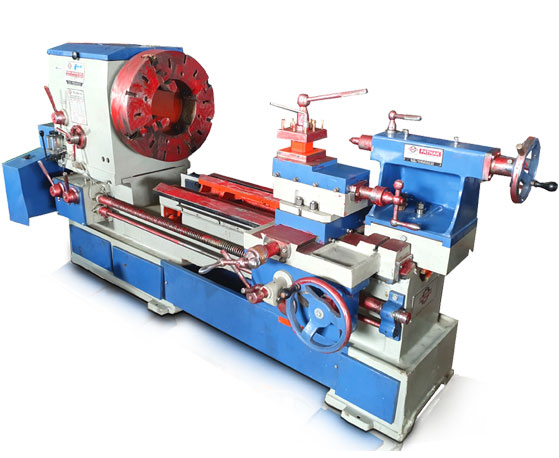

Face Plate : A face plate is a round metallic plate containing work pieces in a lathe. While the work piece is clamped to the face plate of the lathe, turning can begin. It is mainly used for safety and to boost the tool's design and look.

Dog Plate : A lathe canine is a mechanical tool typically fabricated from solid iron, metal, or aluminum that transmits rotary movement from a face plate to a work piece established among facilities in a lathe.

Types of Lathe machine

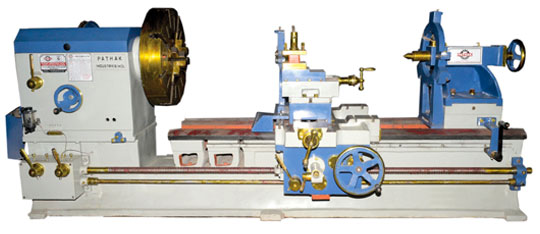

Particular purpose: A special purpose lathe that performs only special operations can not be possible with a standard machine. This lathe machine is used for heavy-duty production.

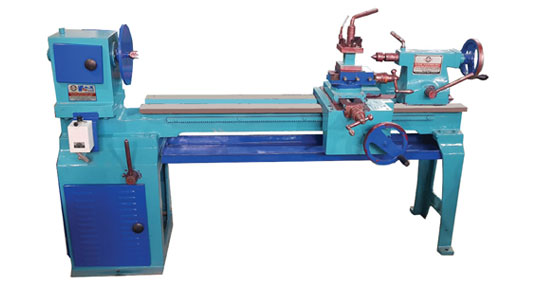

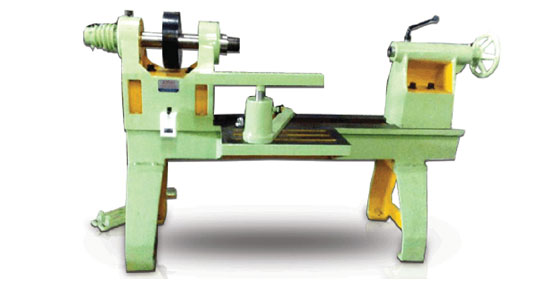

Speed Lathe : this Lathe machine is used for polishing, spinning, centering, and wood. The speed ranges of the lathe machine from 1200 RPM to 3600 RPM. Lathes are having single pulley constant speed or geared-head drive.

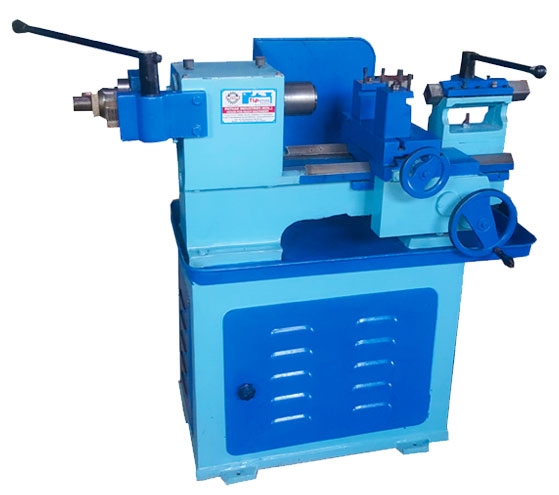

Bench Lathe : The bench lathe machine is mounted on the workbench and combines all parts of the speed lathe machine and engine lathe machine. It is used for small and actual work since it is very accurate.

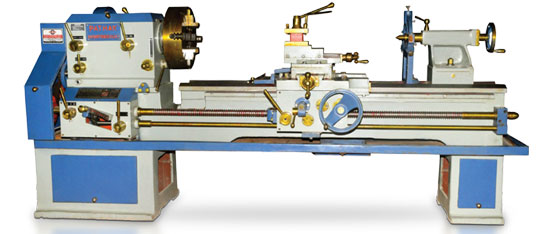

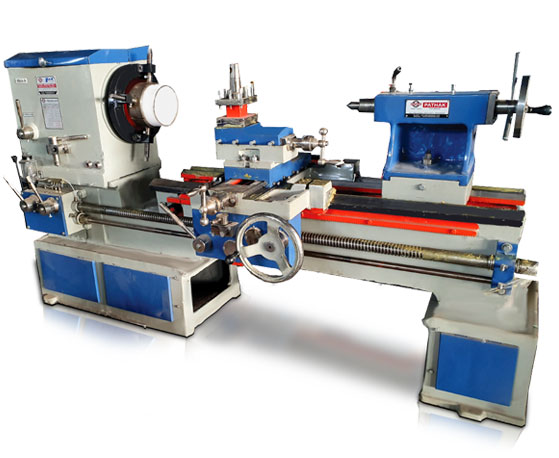

Toolroom Lathe : the Tool room machine is used for die gauges and grinding; this machine works with high accuracy. It required 2500 RPM to work.

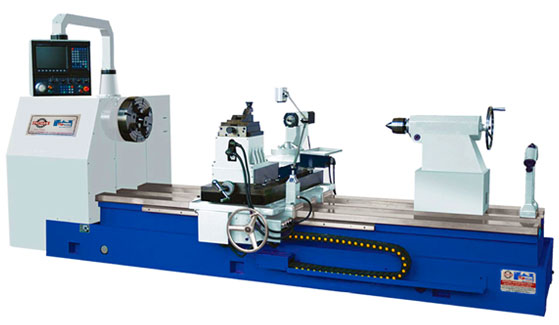

Engine Lathe: engine lathe is a widely used lathe; it resembles a speed lathe in most of its features; it carries a combination of gears; instead of the cone pulley and back gears combination, the lathe is known as geared head lathe and the head stock as all geared head stock.