Threading Machines Manufacturer in India Best Price Guarantee

As anyone in the manufacturing industry knows, threading machines are an essential part of the production process. In this article, we'll take a closer look at what exactly threading machines are and how they work. Threading machines are used to create screw threads. The process is relatively simple - a die with a spiral groove is rotated against the workpiece, which cuts a thread into it. The die is then removed and the newly-threaded workpiece is checked for accuracy. There are many different types of threading machines, each with its own unique capabilities. In general, though, all threading machines work in basically the same way. By understanding how these machines work, you'll be able to better select the right one for your manufacturing needs.

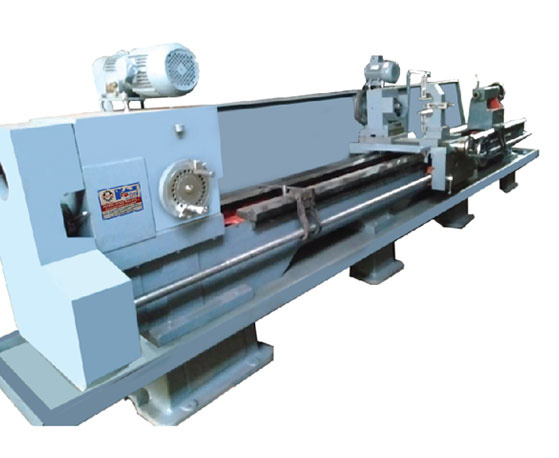

What is a threading machine ?

A threading machine is a machine that is used to create screw threads. This can be done by hand, but it is usually done by using a lathe.

The different types of threading machines

Threading machines are used to create screw threads. There are three main types of threading machines:

- CNC Threading Machine: A CNC threading machine is a computer-controlled machine that is used to create screw threads.

- Manual Threading Machine: A manual threading machine is a hand-operated machine that is used to create screw threads.

- Hydraulic Threading Machine: A hydraulic threading machine is a machine that uses hydraulic pressure to create screw threads.

How does a threading machine work ?

A threading machine is a machine that is used to create screw threads. The way that a threading machine works is by taking a piece of metal and using a tool to cut grooves into it. These grooves are what will become the threads of the screw.

The benefits of using a threading machine

If you're looking for a way to create screw threads, a threading machine is the way to go. Threading machines offer a number of benefits over other methods of creating screw threads, including:

Increased precision

With a threading machine, you can achieve much greater precision than with other methods of creating screw threads. This is due to the fact that the machines are able to cut the threads with much greater accuracy.

Increased speed

Threading machines can also create screw threads much faster than other methods. This is due to the fact that the machines can cut the threads much more quickly.

Increased durability

Screws created with a threading machine are also much more durable than those created with other methods. This is due to the fact that the threads are cut much more precisely, which results in less wear and tear over time.

How to choose the right threading machine for your needs

There are many different types of threading machines on the market, each with its own unique set of features and benefits. So, how do you choose the right one for your needs? Here are a few things to consider:

- The type of thread you need to create. There are machines designed for both metric and imperial threads.

- The materials you'll be working with. Some machines are better suited for softer materials, while others can handle tougher materials.

- The level of precision you need. If you're creating threads for critical applications, you'll need a machine that's capable of very precise tolerances.

- Your budget. Threading machines can range in price from a few hundred dollars to several thousand dollars.

- Once you've considered all of these factors, you should have a good idea of which type of threading machine is right for you.

In conclusion, threading machines is the process of creating a screw thread. This can be done with either a die or a tap. The main advantage of using a machine is that it is much faster and easier to use than doing it by hand. There are also many different types of machines available that can be used for this purpose. When choosing a machine, it is important to consider the type of thread you need to create, the materials you'll be working with, the level of precision you need, and your budget. Once you've considered all of these factors, you should have no problem finding the perfect threading machine for your needs.