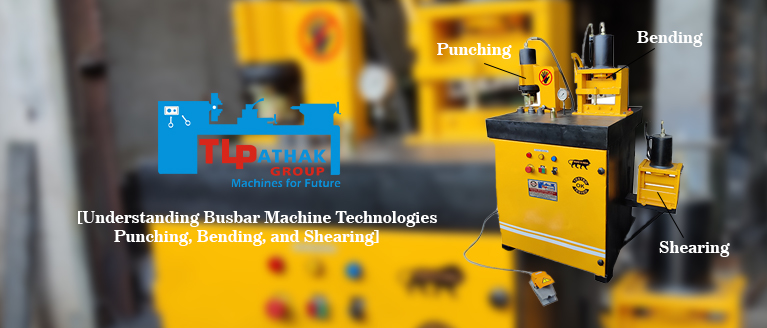

Understanding Busbar Machine Technologies Punching, Bending, and Shearing

Published On: Jun 15, 2023 by Pathak

Exploring Busbar Machine Technologies: Punching, Bending, and Shearing -

Introduction:

a. Introduce the concept of busbar machine technologies and their crucial role in busbar fabrication and assembly.

b. Highlight the significance of understanding punching, bending, and shearing processes for efficient manufacturing.

1. PUNCHING OPERATION:

The punching function of a busbar machine is a crucial process in busbar fabrication. It involves creating precise holes, cutouts, or slots in the busbars to accommodate electrical components, connectors, or mounting hardware. Here's a description of the punching function:

a. The punching function utilizes specialized tools, such as punches and dies, to create clean and accurate perforations in the busbars. These punches and dies can be customized to match specific hole patterns, shapes, and sizes required by the electrical design.

b. The busbar material, typically copper or aluminum, is positioned and secured in the machine's work area. The punching mechanism, driven by hydraulic or servo motors, applies controlled force to the selected punch and die set, resulting in the creation of holes or cutouts in the busbar.

c. The punching function offers several advantages. Firstly, it ensures precise alignment and positioning of the perforations, facilitating seamless installation and connection of electrical components. It also enables high-speed production, allowing for efficient manufacturing in large volumes.

Furthermore, the punching function provides repeatability, ensuring consistent hole dimensions and shapes across multiple busbars. This uniformity is crucial for reliable electrical connections and compatibility with standardized components.

Additionally, the punching function allows for versatility in creating various hole patterns to suit specific requirements. This flexibility enables the busbar to accommodate different types of connectors, terminals, or accessories, enhancing the overall functionality and adaptability of the electrical system.

Overall, the punching function of a busbar machine plays a pivotal role in achieving precise and customized perforations, ensuring optimal compatibility, efficiency, and reliability in busbar fabrication.

2. BENDING OPERATION :

The bending function of a busbar machine is an essential process that enables the shaping and forming of busbars to fit specific electrical configurations. Here's a description of the bending function:a. The bending function of a busbar machine utilizes specialized bending tools, such as punches and dies, to bend and shape busbars into desired angles or curves. The busbar material, commonly copper or aluminum, is positioned and secured within the machine's bending area.

b. The bending mechanism, driven by hydraulic or servo motors, applies controlled force to the bending tools, gradually deforming the busbar material into the desired shape. The machine's design and precision controls ensure accurate and consistent bends across multiple busbars.

c. The bending function offers several advantages. Firstly, it enables customization and flexibility in adapting busbars to specific electrical layouts. By precisely bending the busbars to required angles, it allows for optimal fitment within enclosures or panels, maximizing space utilization and ensuring proper connection with electrical components.

Furthermore, the bending function facilitates the creation of uniform bends, ensuring consistent electrical performance and reliable connections. It ensures that the bends maintain their shape and do not deform or loosen over time, contributing to the longevity and stability of the electrical system.

The bending function also enables the formation of complex shapes and configurations in busbars, such as U-bends or Z-bends, to meet specific project requirements. This versatility allows for adaptability in various applications, including switchgear manufacturing, power distribution, and control systems.

Moreover, the bending function contributes to streamlined production processes, as it eliminates the need for manual bending or forming of busbars. It enhances efficiency, reduces labor costs, and increases overall manufacturing throughput.

Overall, the bending function of a busbar machine plays a crucial role in achieving precise and customized bends, ensuring optimal fitment, electrical performance, and efficient busbar fabrication.

3. SHEARING OPERATION :

The shearing function of a busbar machine is a key process in busbar fabrication that involves cutting busbars cleanly and accurately to desired lengths. Here's a description of the shearing function:

a. The shearing function of a busbar machine utilizes specialized shearing tools, such as blades or cutting mechanisms, to swiftly and precisely cut busbars. The busbar material, typically copper or aluminum, is positioned and secured within the machine's shearing area.

b. The shearing mechanism, driven by hydraulic or servo motors, applies controlled force to the cutting tools, resulting in a swift and clean cut across the busbar. The machine's design ensures stability and support, enabling accurate and straight cuts without material distortion.

c. The shearing function offers several advantages. Firstly, it provides clean and burr-free cuts, resulting in smooth edges that facilitate easy installation and connections in electrical systems. This clean-cutting capability minimizes the need for additional deburring or finishing processes.

Additionally, the shearing function ensures accuracy and repeatability, producing consistent busbar lengths across multiple pieces. This uniformity is crucial for maintaining proper alignment, fitment, and electrical performance in various applications.

The shearing function contributes to high-speed production, allowing for efficient manufacturing of busbars in large quantities. This efficiency enhances productivity and reduces production lead times, enabling timely delivery of busbars for projects.

Moreover, the shearing function offers flexibility in adjusting busbar lengths to specific requirements. By precisely cutting busbars to desired sizes, it enables customization and ensures optimal utilization of space within electrical enclosures or panels.

Overall, the shearing function of a busbar machine plays a vital role in achieving accurate and clean cuts, ensuring precise fitment, electrical performance, and efficient busbar fabrication.

Conclusion:

a. Summarize the significance of understanding punching, bending, and shearing technologies in busbar machines for efficient busbar fabrication.

b. Emphasize the role of these technologies in achieving precision, customization, and streamlined production processes in the electrical industry.

Lastest Articles

-

Embracing NC Hydraulic Press Brake Technology in Middle East Factories

Being a prominent center for indust... -

What machines are used to set up an Electrical Modular Box Plant

Attention all aspiring entrepreneur... -

Manual Process For Making Steel Almirah

Steel almirah are not only durable ... -

Semi Automatic Almirah Making Machines

Streamlining Production Processes w... -

Steel Almirah Manufacturing With Fully Automatic High Precision Machines

Welcome to the world of precision a... -

Unlocking the Power of Precision Understanding the Purpose and Functionality of Drilling Machines

A drilling machine is a tool used f... -

A Beginners Guide to C-Frame Presses for Industrial Applications

Welcome to the world of C-frame pre... -

Busbar Machine Applications in Automotive Manufacturing

Busbar Machine Applications i... -

How Busbar Machines Contribute to Electrical Safety and Reliability

How Busbar Machines Contribute to E... -

A Beginner's Guide to Busbar Fabrication and Assembly

A Beginner's Guide to Busbar Fabric...