The Lathe Machine The Mother of all Machines And A Precursor to Every Machine Tool

The Lathe Machine is one of the oldest machine tools in the production machine. This Machine is also known as the “mother of all machines." Lathe machine is probably the oldest machine know to mankind. Indeed, it was not until about 400-500 years ago, when some of these machines were turned into practical devices for turning wood and metal into products. We are going to explain what lathes are and how they developed over time.

What is a Lathe Machine ?

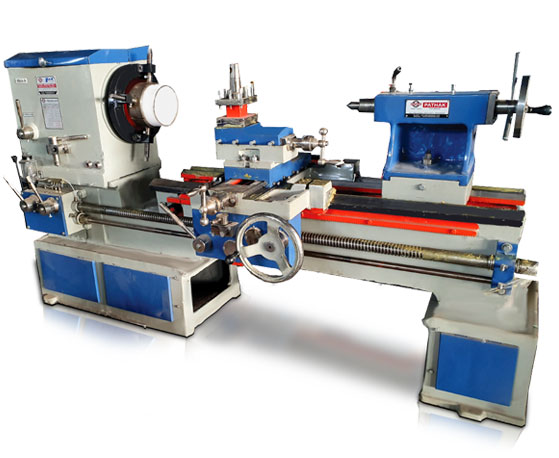

A lathe machine is a machine tool that is used for shaping or machining various materials. It is also known as the mother of all machines and a precursor to every machine tool. Lathes were first invented in ancient Egypt and were later developed in China, Greece, and Rome. They were then introduced to Europe in the 13th century. Lathes work by rotating a workpiece on a spindle while a cutting tool is applied to the workpiece. The cutting tool can be moved along the length of the workpiece to create different shapes and sizes. Lathes are used to create everything from small objects like coins to large objects like airplane parts. There are many different types of lathe machines, but they all operate on the same basic principle. The most common type of lathe machine is the engine lathe, which is used for general machining operations. Other types of lathes include turret lathes, capstan lathes, and gang lathes.

Basic Function of A Lathe Machine

A lathe machine is a tool that is used to shape and form materials such as metal, wood, and plastic. It is one of the most versatile tools in a machine shop and can be used to create a variety of different parts and products. The basic function of a lathe machine is to rotate a workpiece (usually cylindrical) while a cutting tool is applied to the workpiece to remove material and create the desired shape. Lathe machines are often classified by the type of cutting tool that they use. The most common type of lathe machine is the center lathe, which uses a single-point cutting tool. Other types of lathes include engine lathes, turret lathes, and CNC (computer numerical control) lathes. Each type of lathe machine has its own advantages and disadvantages, but all are capable of producing high-quality parts and products. No matter what type of lathe machine you use, the basic operating principle is the same: a workpiece is rotated while a cutting tool removes material to create the desired shape. Lathe machines are an essential part of any machine shop and are used in a wide variety of industries such as aerospace, automotive, medical, and more

The Largest Machine Tool

The lathe machine is the largest machine tool in existence and is a precursor to every machine tool. It is a massive machine that can be used to create incredibly intricate parts and shapes. The lathe machine is so important because it is the foundation upon which all other machine tools are built. Every machine tool that exists today has its roots in the lathe machine.

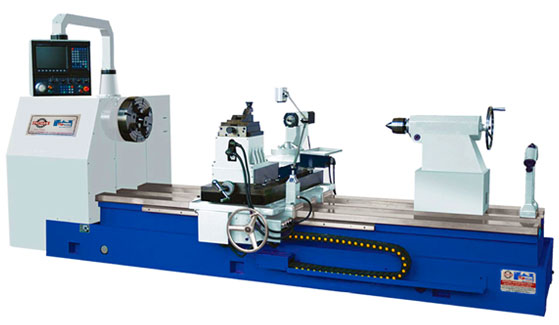

Lathe Machines in the Modern Age

The lathe machine is the mother of all machines, and a precursor to every machine tool. It is a versatile tool that can be used to create a variety of objects, including tools, parts, and components. The lathe machine has been around for centuries, and its popularity has only increased in recent years. There are many different types of lathe machines available on the market today. Each type of machine has its own unique capabilities and features. Lathe machines can be used for a variety of applications, including turning, drilling, reaming, and threading. Lathe machines are an essential part of any machinist's shop. They are versatile tools that can be used to create a variety of parts and components. If you are in the market for a lathe machine, there are many different types and models to choose from. With so many options available, it is important to do your research to find the best machine for your specific needs.

Alternatives to Lathe Machines

There are a few alternatives to lathe machines that can be used for machining. These include:

Milling machines

Milling machines are similar to lathe machines in that they both have rotating cutting tools. However, milling machines also have a moving table that the workpiece is attached to. This allows for more complex shapes to be machined.

CNC machines

CNC (computer numerical control) machines are automated versions of milling machines or lathe machines. A CNC machine is programmed to follow a set of instructions to create a part.

EDM Machines

EDM (electrical discharge machining) uses electrical sparks to remove material from a workpiece. This process is typically used for harder materials that are difficult to machine with traditional methods.