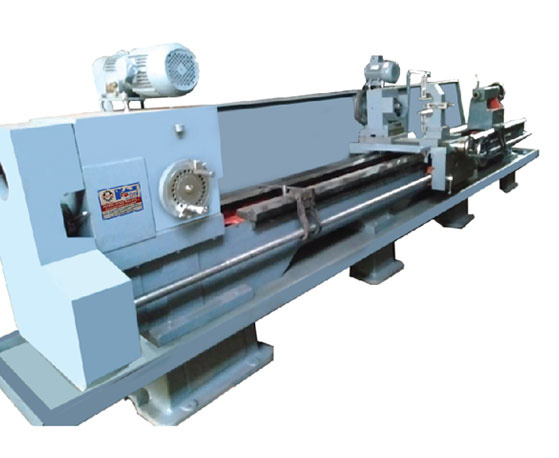

Threading Machine Manufacturer in Odisha Paradeep

A threading machine is most commonly used in the piping industry. This device is used to create the threads found on the outside of pipes. The machine consists of a die, which is a metal block with a hole in it that is the same shape as the threads you want to create. The die is attached to a handle, which is then turned to cut the threads into the pipe.

What is a Threading Machine ?

A threading machine is a device that is used to create the threads found on pipes. This type of machine is typically used in industrial settings, as it is capable of creating a wide variety of threads. There are two main types of threading machines: automatic and manual. Automatic threading machines are faster and more precise than manual ones, but they can be more expensive. Manual threading machines require the operator to guide the cutting tool, which can be less precise. Both types of machines are used to create internal and external threads. Internal threads are found on the inside of a pipe, while external threads are found on the outside. To create an internal thread, the cutting tool must be smaller than the pipe's inner diameter. To create an external thread, the cutting tool must be larger than the pipe's outer diameter. Threading machines can be used to create a variety of different threads, depending on the application. The most common type of thread is the American National Standard Pipe Thread (ANSI/ASME B1.20.1), which is used for general purpose piping applications. Other types of threads include metric threads, British Standard Pipe Threads (BSPT), and United

The Different Types of Threading Machines

There are many types of threading machines, each designed for a specific type of threading. The most common types of machines are the lathe, the tap drill, and the die. The lathe is the most versatile type of machine, capable of creating both internal and external threads. It consists of a bed, a headstock, and a tailstock. The workpiece is mounted on the bed and held in place by the headstock and tailstock. The cutting tool is mounted on the headstock and is fed into the workpiece as it rotates. The tap drill is used to create internal threads, such as those found on screws and pipes. It consists of a drill bit that is inserted into the workpiece and turned in a clockwise direction. As the bit turns, it cuts threads into the sides of the hole. The die is used to create external threads, such as those found on nuts and bolts. It consists of a die that is mounted on the end of a handle. The die is inserted into the workpiece and turned in a counterclockwise direction. As it turns, it cuts threads into the surface of the workpiece.

How to Use a Threading Machine

If you need to cut threads into a pipe, you'll need to use a threading machine. This device is specially designed to create the threads found on pipes, and it's not difficult to use once you understand the basics. Here's a quick guide to using a threading machine:

1. Set up the machine according to the manufacturer's instructions. This will usually involve attaching the pipe to the chuck and tightening it in place.

2. Select the type of thread you need to cut (e.g., NPT or BSP) and the appropriate die from the machine's tooling options.

3. Align the die with the start of the pipe, making sure that it's perpendicular to the surface.

4. Start the machine and let it run until the die has cut all the way through the pipe.

5. Stop the machine and remove the pipe from the chuck. Inspect the threads to make sure they're cut correctly.

Pros and Cons of Using a Threading Machine

Threading machines are used to create the threads found on pipes. There are both pros and cons to using a threading machine. The main pro is that it speeds up the process of creating threads. The main con is that it can be difficult to use and can damage the pipe if not used correctly.

Where to Buy a Threading Machine

If you're in the market for a threading machine, there are a few things you should keep in mind. First, decide what type of threading machine you need. There are several different types available, each designed for specific tasks. Second, consider your budget. Threading machines can be expensive, so you'll need to make sure you can afford the one you want. Third, think about where you'll be using the machine. Some machines are designed for home use, while others are meant for commercial or industrial settings. Once you've considered these factors, you're ready to start shopping for a threading machine that meets your needs.

There are a few different places you can buy a threading machine. One option is to purchase one from a local retailer. Another option is to buy online from a specialty retailer. You can also find used machines through online auction sites or classifieds websites. No matter where you purchase your machine, be sure to do your research to ensure you're getting a quality product at a fair price.

Conclusion

A threading machine is a versatile and essential tool for anyone who works with pipes. By using this device, you can create threads on pipes of all sizes quickly and easily. Whether you need to thread pipes for plumbing or other purposes, a threading machine can help you get the job done right.